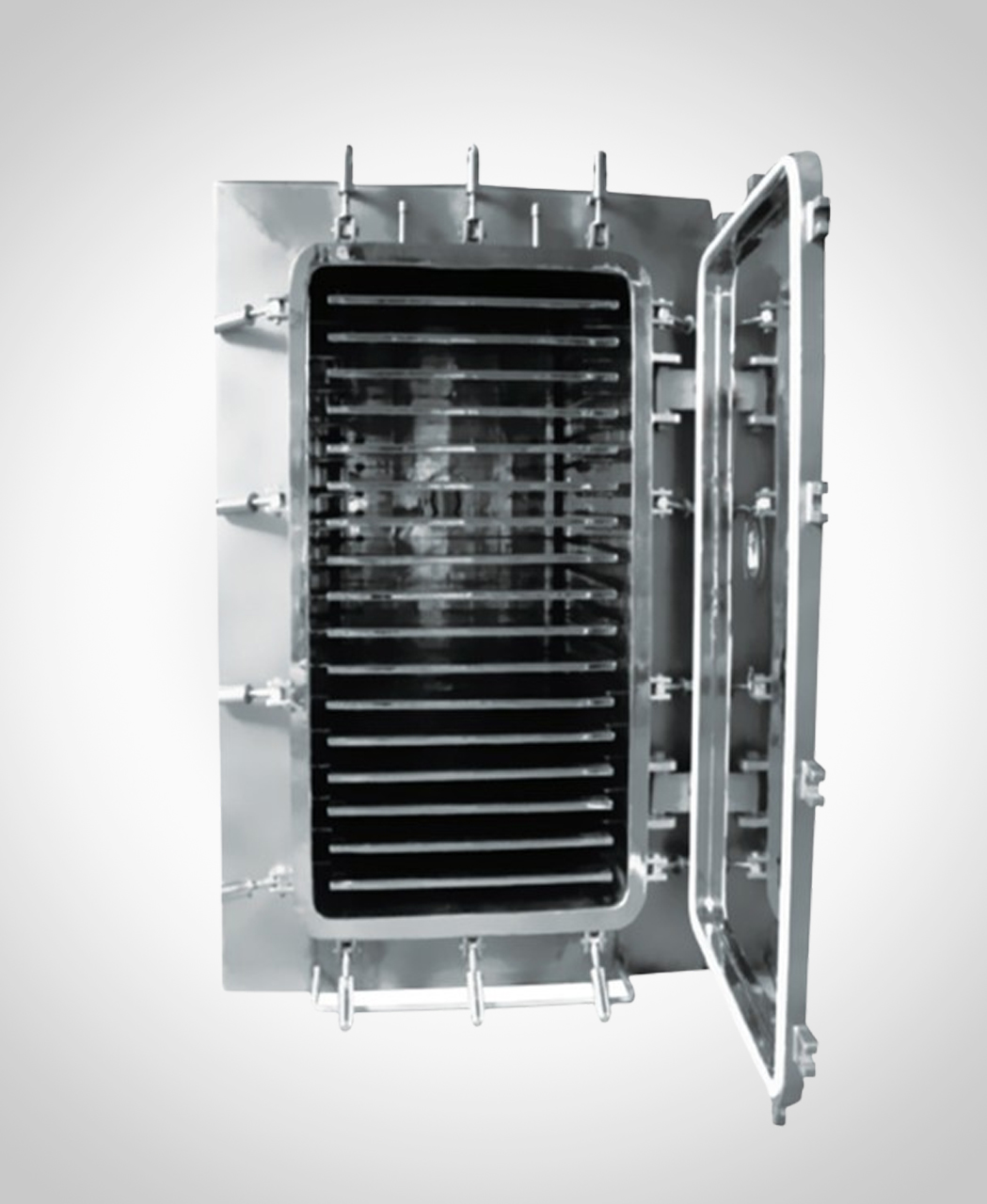

Vacuum Tray Dryer (VTD) is drying machines especially useful in pharmaceuticals, chemicals, and food processing. They excel at removing moisture from wet materials under controlled conditions with lower pressure (vacuum). This vacuum environment allows drying at much cooler temperatures compared to other methods, making them ideal for materials that are sensitive to heat.

Vacuum Dryer works on the concept that a vacuum is created inside the drying chamber making the boiling point of the liquid existed in the material lower. This process causes the moisture to evaporate at relatively lower temperatures, while at the same time protecting the heat sensitive compounds.

Aquaon Engineers is a well-known vacuum tray dryer manufacturer, exporter, and supplier in Mumbai, India. A vacuum dryer is an indispensable tool in industries requiring accurate and efficient drying of sensitive materials. Its capacity to operate under vacuum conditions makes it a versatile and reliable choice for maintaining the quality and integrity of various products. Whether in pharmaceuticals, food processing, or chemical manufacturing, the Vacuum Tray Dryer stands out as a superior drying solution.

| Brand | AQUAON Engineers | |||

| Capacity | 1 / 3 / 6 / 12 / 24 / 48 / 72 / 96 Trays | |||

| Temperature Range | Typically, between 30°C to 150°C, adjustable based on product requirements. | |||

| Heat Source | Electric | |||

| Vacuum Levels | Can reach up to 0.1 torr, ensuring efficient moisture removal. | |||

| Material | Made from stainless steel (SS 304 or SS 316) to ensure durability and resistance to corrosion | |||

| Control Systems: | Advanced PLC (Programmable Logic Controller) systems for precise control and automation of the drying process. | |||

| Usage | Industrial | |||